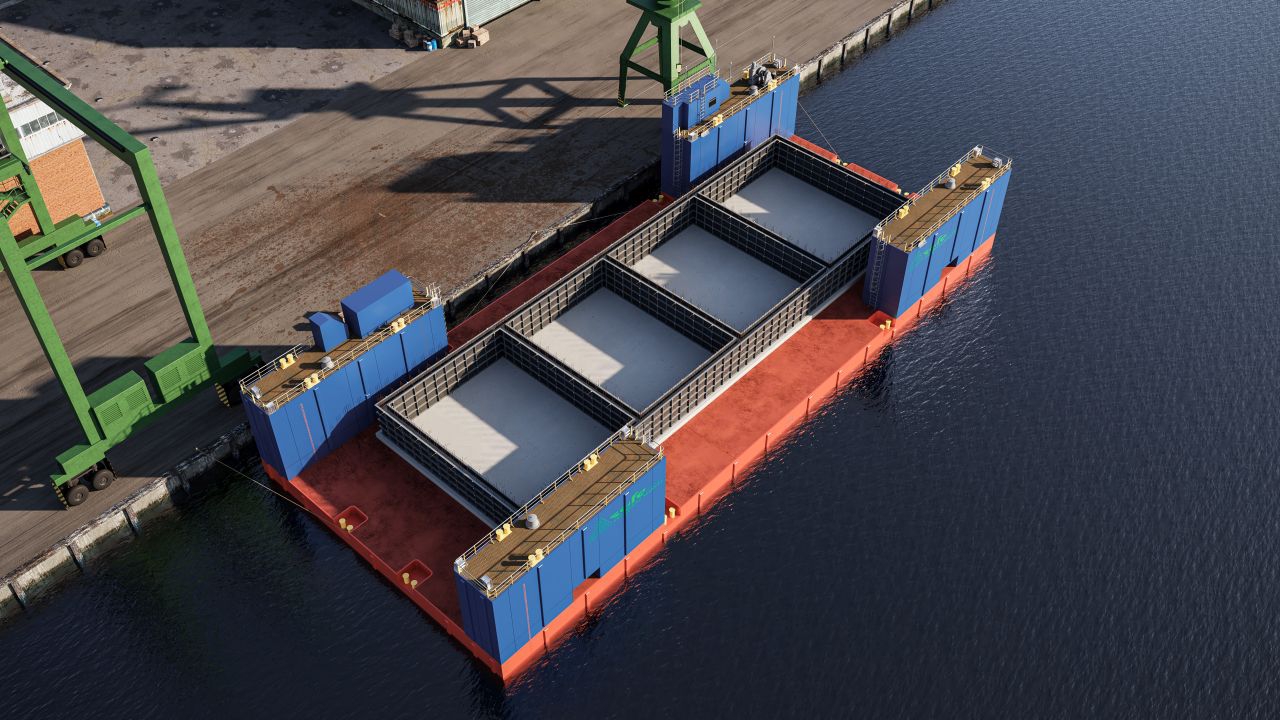

We are designing and building Floating Docking Platform (PPD)

03.12.2021

Floating Docking Platform (PPD) is a multi-functional floating vessel dedicated to a wide range of customers: shipyards, offshore sector, hydro-technical facilities contractors, and seaports.

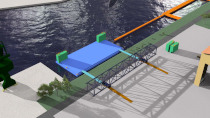

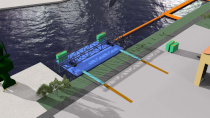

The platform has docking and transport functions in both water-land and land-water directions. The technology of docking of floating vessels developed by Safe enables taking an object from the water, its transport on the modular transport carts (SPMT) to the wharf and further on the land.

PPD is equipped with a specialized unloading ramp designed for a low bearing capacity wharfs (under 2 tones). Transport features of PPD enable sailing in the wind of 5 Beaufort. The range is 200 nautical miles from the refugee harbor. It’s possible to deliver the load to a customer in any place in Europe.

A software solution is an integral part of the project. It guarantees continuous monitoring of the loading process as well as the monitoring and data required to control the ballast system. At the same time, it’s possible to monitor what’s going on the verge of the wharf, land, and the pontoon. The algorithm will help to calculate the financial aspects of the entire operation as well.

The project has already been approved by the classifier, Polski Rejestr Statków. Currently, the construction process is in progress. The project should be finished in approximately 12 to 16 months.

More information

The platform has docking and transport functions in both water-land and land-water directions. The technology of docking of floating vessels developed by Safe enables taking an object from the water, its transport on the modular transport carts (SPMT) to the wharf and further on the land.

PPD is equipped with a specialized unloading ramp designed for a low bearing capacity wharfs (under 2 tones). Transport features of PPD enable sailing in the wind of 5 Beaufort. The range is 200 nautical miles from the refugee harbor. It’s possible to deliver the load to a customer in any place in Europe.

A software solution is an integral part of the project. It guarantees continuous monitoring of the loading process as well as the monitoring and data required to control the ballast system. At the same time, it’s possible to monitor what’s going on the verge of the wharf, land, and the pontoon. The algorithm will help to calculate the financial aspects of the entire operation as well.

The project has already been approved by the classifier, Polski Rejestr Statków. Currently, the construction process is in progress. The project should be finished in approximately 12 to 16 months.

More information